We have been approached by a property manager of one of many of London's synagogues to investigate and possibly help with the recreation of the traditional terrazzo floor. The floor has been done in the early 20th century and lately been damaged during some remedial work around burst water mains.

Prepartion

We have done some research and priced the job correctly. at the same time we've advised the client that the whole floor needs to be removed - one can not patch terrazzo to make "invisible" repairs. After instructing the client's contractor how to prepare the surface for terrazzo we have started the preparation of the mosaics.

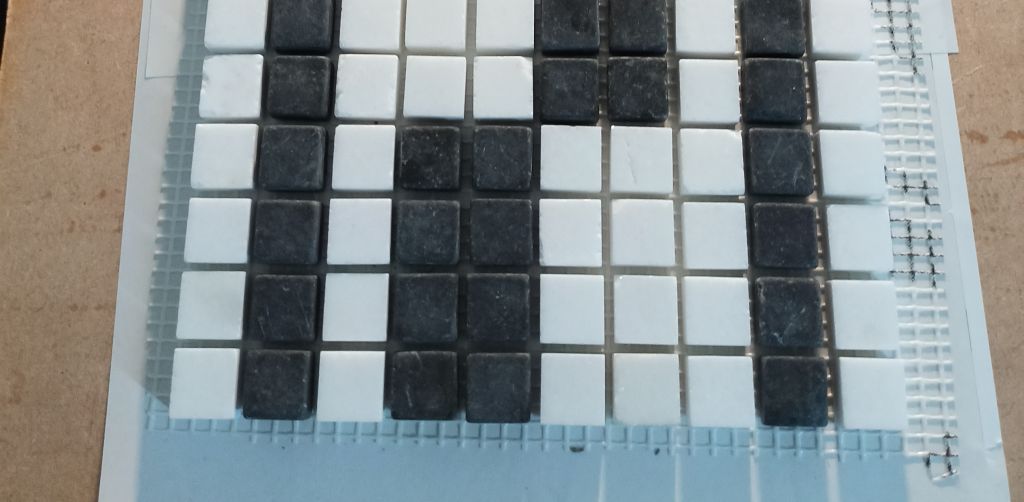

The mosaics have been recreated using marble cubes 15x15mm. Our most patient employee embarked on a mission to make patterns, handpick all the marbles cubes and create almost 30 linear meters of the inlay and glue it to a glass fibre mesh.

Meanwhile, we've started the preparation for the installation starting with treating the substrate with vetrofluid - waterproofing solution and concrete densifier. The next step was the application of a thin layer of epoxy resin with quartz sand.

As soon as the resin has cured our mosaics specialist started to install the marble inlay. The whole operation took just 3 days and the effects were stunning. The inlay looked perfect. The only thing that was missing was the terrazzo.

Terrazzo installation

Once the mosaics have been installed creating a level reference for the terrazzo, the pouring has started. Pouring a 15mm layer of terrazzo is quite a laborious process and takes the whole day. But the floor requires power floating. Power floating can only be done once the terazo has dried enough to allow it, but not too much so it can still be power floated.

Power floating leaves the surface fairly smooth and even. At this point, the floor has to be left for 28 days for curing. We regulate the rate of drying/curing with help of special sealers and thin PE sheets. It is crucial not to let the mix dry too fast. The first lockdown extended the curing process quite a bit but we have returned to polish the floor using our HTC floor grinders.

Finishing and aftercare

After almost a week of grinding and polishing the floor was finally ready for sealers. sealers protect the terrazzo floor from staining and give it more shine..

The final effect was stunning. Some of you may notice that the colour of the floor is different from the original one - that was the client choice 😉