Contemporary style with microcement

High-quality microcement is a great material for flooring, wall finishes and even work surfaces and furniture. Extensive choice of colours and finishes allows for full flexibility. It is a product of choice when a minimalist contemporary look is required. The seamless surface of micro-cement, when compared to tiles with grouting lines looks cleaner. Also much more sophisticated, yet at the same time simple. Extremely durable although quite thin, microcement can be applied to most of the stable substrates, including wood, ceramics etc. because it is only 2-3 mm thick, your new floor will not affect door height. This makes it cost-effective compared to the new wooden floor or tiles.

Different types of cementitious overlays

There are many cementitious flooring products on the market and they usually fall into one of two categories: resin-based and water-based. What is resin-based micro-cement? It is usually a cement derived powder containing quartz sand and pigment bonded by some sort of resin. This is the most popular kind of concrete looking product available on the market. Its advantage is the speed of curing, disadvantage is the speed of curing, hardness and VOC content.

Water-based cementitious overlays on the other hand consist of cement, aggregate, polymer bonding agent and water that is responsible for the cement curing process. Because there is no resin in it, this means it is a zero VOC product. Lack of resins also means that the product is more resistant to heat and fire. The downside is the curing time that is closer to concrete than to epoxy. The next layers can only be added on the following day.

Surface preparation

Microcement is to be applied to substrates with less than 10% MVTR (Moisture Vapour Transmission Rate). On floors, the concrete screed should be fully cured before application of microcement (28 Days). When applied on other substrates like wood, plaster or plasterboards, all the joints have o be filled and sanded like for wallpaper or paint. Microcement is flexible but it does not stretch so it will develop a crack when the substrate crack or comes apart. This is why we recommend fibreglass mesh for reinforcing joints. Fix all cracks.

Concrete floor in the basement can be densified with vetrofluid - type B waterproofer and densifierMake sure the surface is even, clean, sturdy, and free of contaminants. It is good when the substrate has uniform absorption as different water absorption may affect the colour pattern on the microcement. Polyfilla filled plasterboard joins are a good example of substrates of different absorption. You may want to use PVA solution to such areas to make them more uniform.

The application of microcement should be no lower than 5 degrees C and no higher than 25 degrees C. When applied externally make sure there is at least a week of good weather ahead. Protect areas from rain and falling leaves.

First layer is important

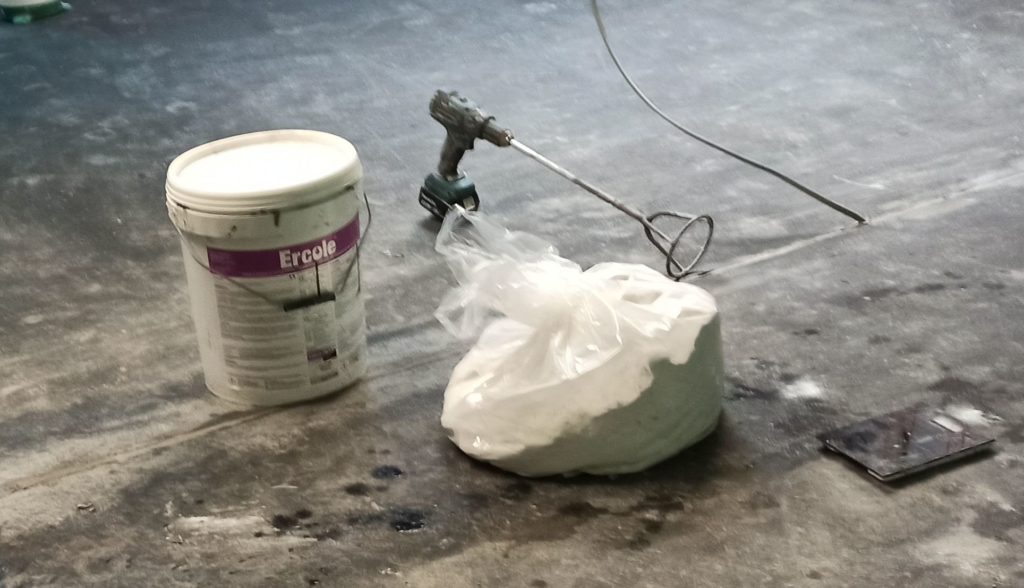

First layer provides bonding to the substrate as well as evens out the surface. It is also a carrier for the finishing layer or layers depending on the choosen finish. We use Ecobeton Ercole as a first layer. Thanks to its quality polymers and quarts sand it provides great strength and durability. It is so tough and water resistant, that it can be used externaly on floors, walls and other surfaces. Before application makes sure underfloor heating is off and the temperature and humidity are within the norm.

Ercole with water is mixed until the desired consistency is achieved. Slow mixers are preferred to prevent air bubbles formation. Depending on the substrate it is applied by squidgy, spatula or trovel within 2 hours from the moment the water was added. The first layer should be left to dry overnight.

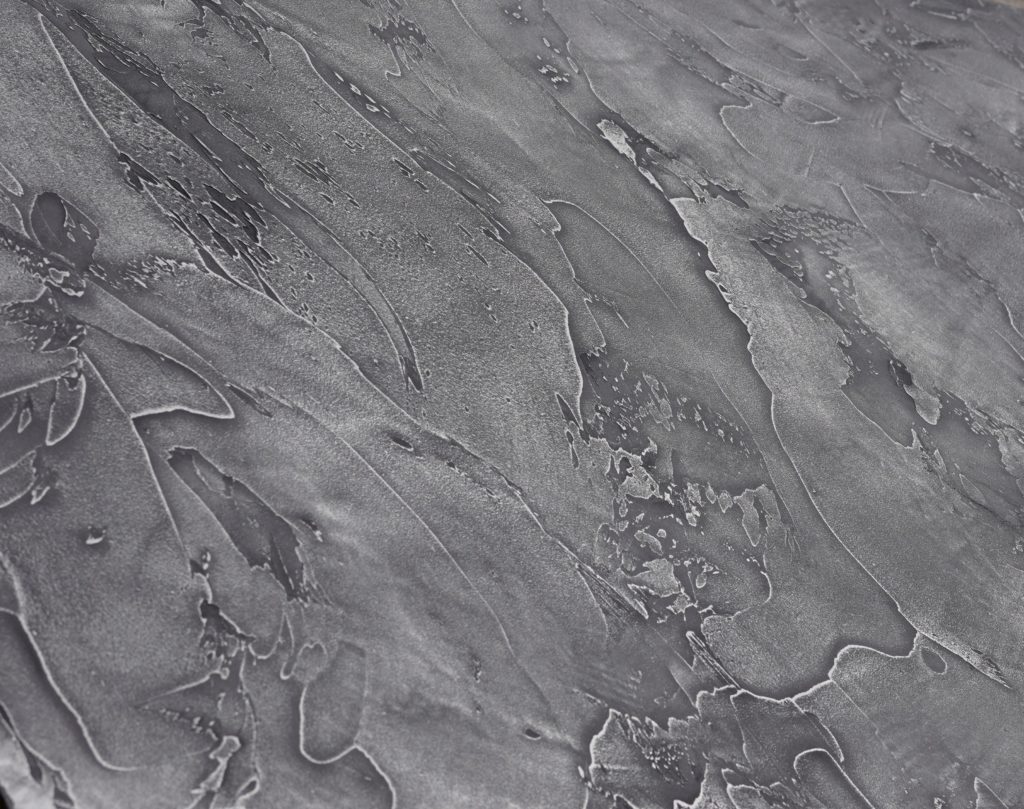

Sanding between the layers

Every layer of microcement has to be sanded down. How much it depends on the application as well as on the final effect you'd like to achieve. All the features and imperfection on base layer will impact the finish layer. All humps, bumps and lines that have been sanded down will have different absorption. Features that have not been sanded and are pertruding from the surface will pop through the next layer. This may result in a features in different colour and texture.

Machine sanding is our preferred method and we do have 450mm disc sanders for floors. Walls are bit more difficult to sand and usually have to be hand sanded.

Finnishing and sealing microcement

There are different styles of micro-cement and at least 3 finishes to choose from but it always starts with a little bit more sanding and primer. The application of micro cement primer is one of the most important processes as the primer primes the surface and enables better sealer adhesion.

Ecobeton sealers come in 3 different finnishes.

- Gi.Gi. Sealer - Very durable and strong micro-cement sealer with satin finish can be used internally and externaly.

- Cercero Sealer Gloss - Thick and shiny microcement sealer

- Cerber Sealer Matt - Micro cement and concrete sealer with matt finish

Once the sealers have been applied the micro-cement floor is ready for curing

Microcement covered furniture

Application of cementitious coatings on furniture is the hard core aspect of microcement. It requires a special preparation of wooden surfaces, different fillers and primers. It also requires that the joints and corners are adequately prepared. Because of the intricate shape it takes much more time and effort and it may not be cost effective to do it on site.

Wthis is why we make and microcement most of the furniture in our workshop located at outskirts of London. This allows us to work on your project in environment we fully controll.

Microcement made out of metal

Instead of cement powder and pigment the coating may consiste of resin paste and metal powder. We've got coatings that are made out of Aluminium, Copper, Bronze as weel as self oxidizing Corten Steel. This sort of coating is being applied the same way as microcements by the means of trovel and spatula. But the final effects are completly different.

We can achieve rusty corten look or liquid aluminum look depending on our client needs. This material can be applied on walls and furniture. Corten can be used on external building fasades.

Prices of microcement

The prices of microcement in London vary, depending on the product used. You'll have to pay anything from 100 pounds up to 250 pounds per 20 kg bucket. The cost of laying microcement is 50-80 pounds per sq. meter on top of that. Depending on the size of the surface, micro-cement installation price may be different, The owner of the 100 sqm apartment will pay less per sq meter than someone just doing 3 sq meter bathroom. On average you can expect to pay a total of 100 - 140 pounds per square meter up to 250 when it comes to covering furniture or other intricate shapes.. It depends on the size of the project and requirements. Depending on requirements we'll provide either resin-based solution or a water-based cementitious compound.

As a London based micro-cement company, we try to stay as competitive as possible without compromising on quality, we're fully committed to delivering an exceptionally good product which will last years in perfect condition. We've been in the trade long enough to know, how important quality is, therefore all our staff is properly trained in micro-cement installation.

Our Team

Always looking to raise qualification, we work closely with manufacturers of micro-cement products keeping our knowledge and expertise at the highest level. Should you have any questions regarding your project or you're not sure if micro-cement is suitable for your property, please contact us and we'll definitely try to help you.

[…] jakości mikrocement to doskonały materiał na podłogi, wykończenia ścian, a nawet powierzchnie robocze i meble. […]